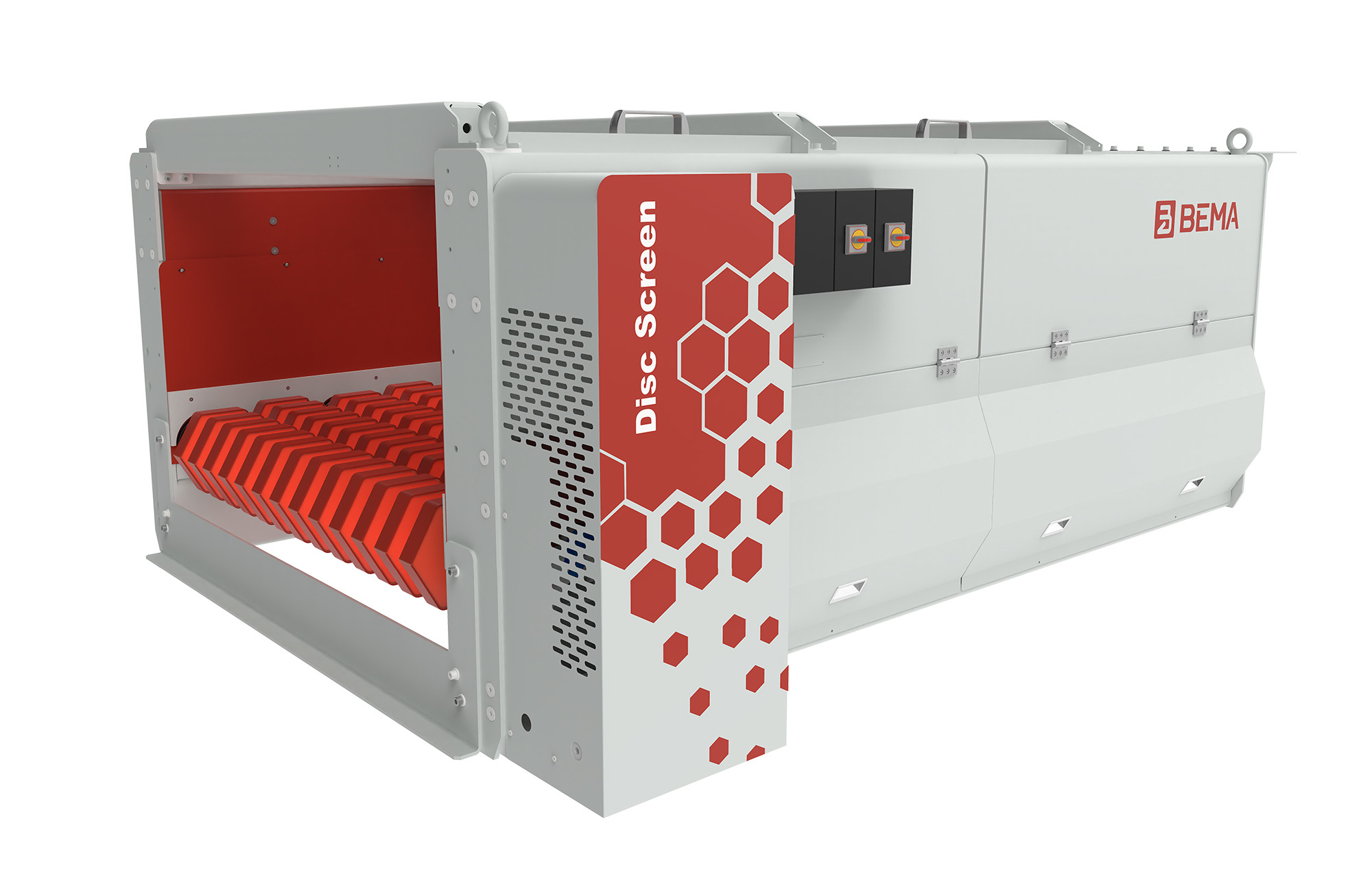

High-speed disc screen for RDF

Release Time:

Jun 13,2025

1. Product Overview

High-speed disc screen for RDF is a high-efficiency screening equipment specially designed for processing refuse-derived fuel (RDF). It plays a vital role in the production process of RDF, and can accurately screen materials to ensure the quality of the final RDF product.

2. Structure and working principle

Structural features

The equipment is mainly composed of multiple high-speed rotating discs. These discs are made of wear-resistant materials with high strength and good corrosion resistance. The spacing of the discs can be adjusted according to actual needs to meet the screening requirements of RDF materials with different particle sizes.

The overall structure is compact and occupies a small area, which is easy to install on RDF production lines of various sizes.

Working principle

It uses rotating hexagonal discs to efficiently separate materials by particle size. Materials that meet the particle size requirements will fall through the gaps between the discs, while larger particles will be blocked by the discs and transported along the disc surface to the other end of the equipment for discharge. This screening method is efficient and accurate, and can quickly classify RDF materials according to particle size.

3. Performance Advantages

High Screening Efficiency

Due to the high-speed rotation of the disc, the material is screened quickly in the equipment, and a large amount of RDF material can be processed in a short time. Compared with traditional screening equipment, it can greatly improve production efficiency and reduce the time cost in the RDF production process.

Accurate Screening

The adjustability of the disc spacing enables it to accurately control the particle size of RDF materials. Whether it is to produce RDF fuel for specific combustion equipment or to meet different quality standards, accurate screening can be achieved by adjusting the disc spacing.

Strong Stability

The equipment adopts an advanced drive system and a stable mechanical structure, which can maintain a stable working state during high-speed operation. This not only ensures the accuracy of screening, but also reduces the failure rate of the equipment and reduces maintenance costs.

4. Application Fields

The High-speed disc screen is widely used in various RDF production plants, including production lines for converting garbage into RDF in urban waste treatment plants, and some companies that produce RDF using a mixture of biomass and garbage as raw materials. It is an important equipment to improve RDF quality and production efficiency.

What Else Might You Learn?

SIDSA focuses on technological research and innovation in the field of waste pretreatment

Product

SIDSA focuses on technological research and innovation in the field of waste pretreatment