SIDSA's full-process equipment empowers Thailand's waste-to-energy conversion!

Release Time:

Aug 11,2025

Garbage is also a resource.

28,800 tons garbage = save 5.85 million USD

In the alternative fuel preparation project in Thailand, the whole line processing capacity can reach 40T/h, and MSW is turning into a real energy gold mine.(Take plastic waste for example)

♻️ Suppose it operates continuously without interruption for 30 days:

✅ Produces 40 tons of high calorific value fuel per hour

🔥 Replaced 45,818 tons of coal

💰 Save fuel purchase costs ¥41,000,000+

🌍 Reduce carbon emissions by nearly 120,000 tons of CO₂!

Whole line process, Strongstrength, More reliable

There is indeed great value hidden in garbage; through resource treatment, MSW can become a 'green fuel' that power plants and cement plants complete for! To effectively address the complex waste composition in Thailand, SIDSA has tailored a MSW resource treatment system for local enterprises.

The entire line uses advanced equipment independently developed by SIDSA, including Primary Shredder, Belt Conveyor, Disc Screen, Air Separator, and the supporting hydraulic station for containers, which can achieve efficient, stable, and reliable operation.

SIDSA equipment meets Swiss quality standards, is safe and durable, uses carefully selected materials, showcases exquisite craftsmanship, and features an overall modular design for easy and quick installation and later maintenance. Each core piece of equipment has excellent performance and strong adaptability.

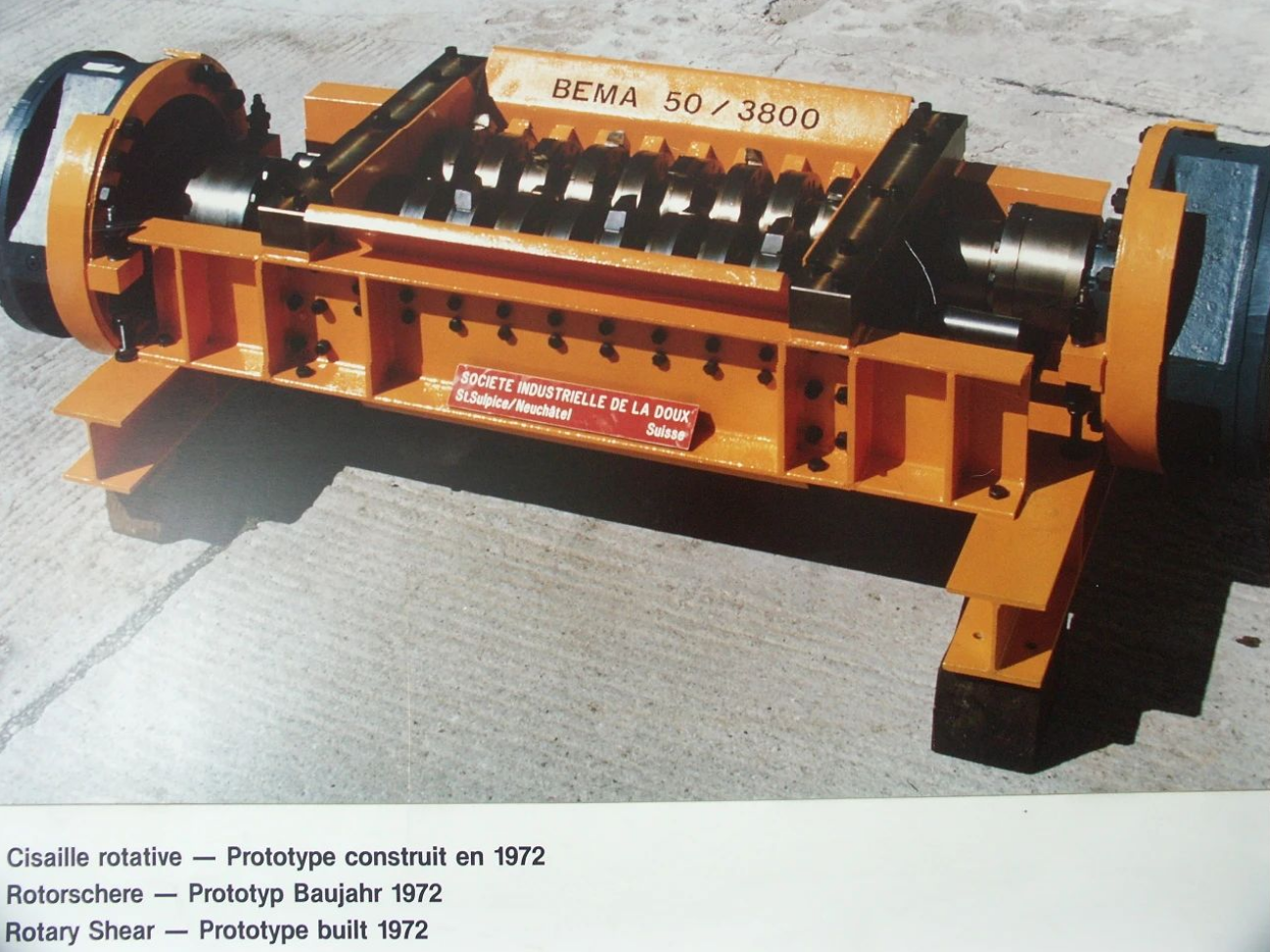

In 1972, SIDSA opened more than 50 years of insist and pursuit

Pay tribute to the past, move on to the future

Since the first SIDSA shredder was launched in 1972, after nearly five decades of wind and rain and market tests, SIDSA has always been dedicated to technological innovation and breakthroughs. Each generation of products is refined and polished in countless field operations, which embodies the wisdom and experience of the technical team.

SIDSA-TECH: Comprehensive Waste-to-Energy Solutions

Throughout its development, SIDSA has not only continuously upgraded its shredding equipment but also expanded its product range, innovatively launching core solid waste processing equipment such as screening and conveying systems. Leveraging quality and experience, SHRED has built an integrated product system covering the entire "Shred - Screen - Separate - Convey" process flow.

Today, SIDSA equipment is widely applied across multiple sectors including municipal solid waste (MSW), bulky waste, construction & demolition (C&D) waste, industrial solid waste, hazardous waste, and recyclables. We empower more cities to achieve green transformation by turning waste into energy.

The core of Swiss quality lies in the relentless pursuit of safety, efficiency, and stability. SIDSA provides clients in all regions with globally unified quality standards. All equipment undergoes strict quality control and rigorous testing to ensure stable operation under diverse and complex working conditions. We also offer 24/7 after-sales service to promptly resolve any issues encountered during operation, providing clients with comprehensive support.

For technical support and project consultation, please leave your contact details and requirements on our official website. We will contact you within 24 hours~!

What Else Might You Learn?

SIDSA focuses on technological research and innovation in the field of waste pretreatment

Product

SIDSA focuses on technological research and innovation in the field of waste pretreatment