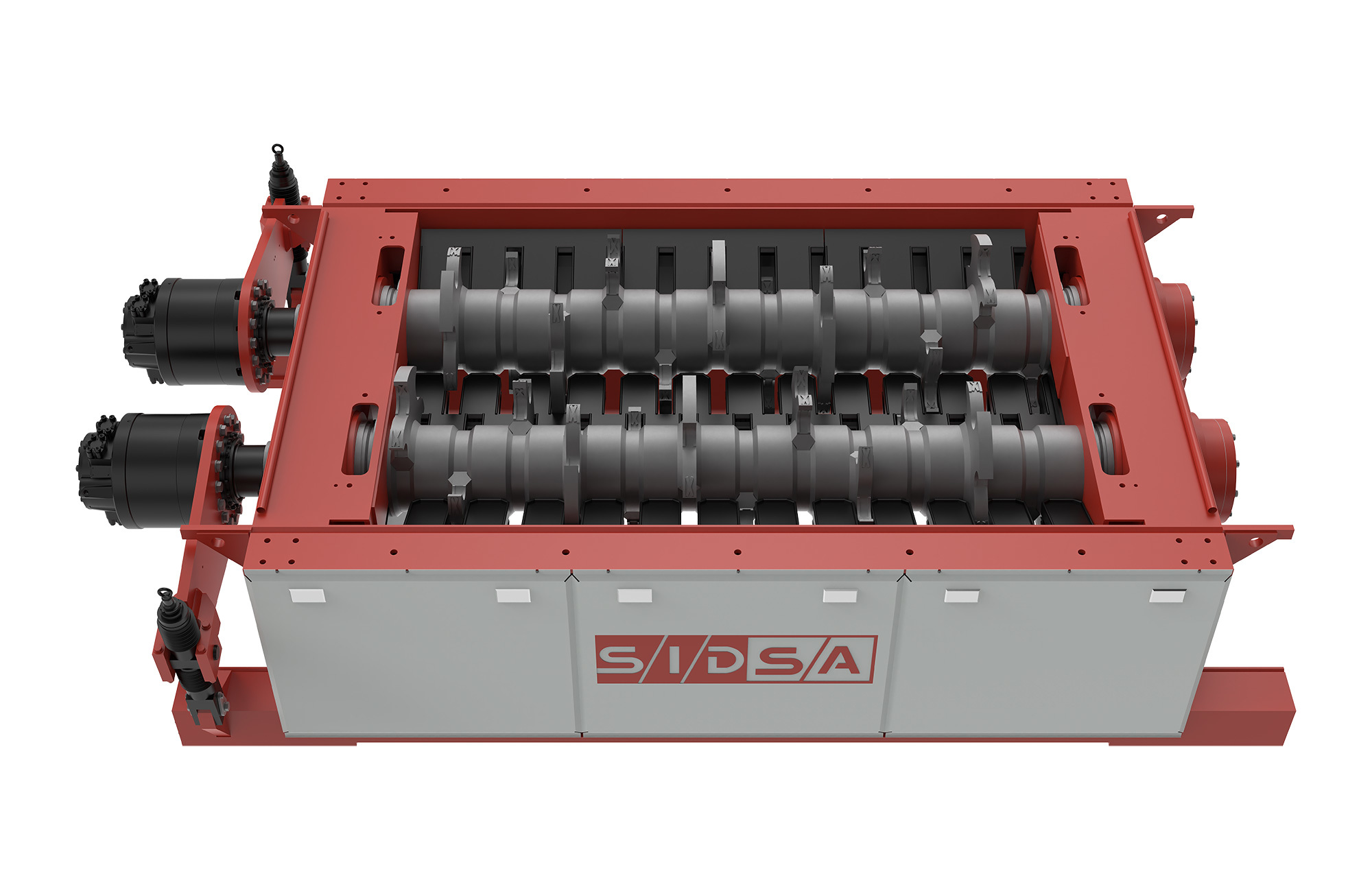

High-torque 2-shaft shredder operation and maintenance points

Release Time:

Jun 06,2025

High-torque 2-shaft shredder plays an important role in the field of material handling. Understanding its operation and maintenance points is essential to ensure the normal operation of the equipment and extend its service life.

1. Operation points

Feed control

Feed evenly to avoid clogging the equipment by putting too much material at one time. For materials of different hardness and size, the feed speed and amount should be reasonably arranged according to the rated processing capacity of the equipment. For example, when processing large block metals, the feed speed should be appropriately slowed down.

Operation parameter monitoring

Pay close attention to the equipment's operating parameters such as torque, speed and temperature. High torque is its characteristic, but if the torque increases abnormally, it may mean that there is a jam or overload inside the equipment. The speed should be kept within the normal range set by the equipment, and the high temperature may be due to long-term operation or abnormal friction of components. It is necessary to check whether the cooling system is working properly in time.

Material adaptation

Ensure that the input material meets the design requirements of the equipment. Although the double-shaft shredder is suitable for a variety of materials, for particularly hard or extremely tough materials, pre-treatment may be required, such as cutting into smaller sizes, to avoid excessive wear on the cutter and equipment.

2. Maintenance points

Cutter maintenance

The cutter is a key component of the High-torque 2-shaft shredder. Check the wear of the cutter regularly, and replace it in time when the cutter is worn to a certain extent. At the same time, keep the cutter clean to avoid material residues from sticking to the cutting effect.

Lubrication system

Regularly check and replenish the lubricating grease of the equipment. Good lubrication can reduce friction between components, reduce energy consumption, and extend the service life of the equipment. Pay special attention to the lubrication of key parts such as bearings.

Regular cleaning

Regularly clean the inside and outside of the equipment. Internal cleaning can prevent material accumulation from affecting equipment performance, and external cleaning can help to promptly detect whether there are cracks, corrosion, etc. on the surface of the equipment. At the same time, clean the working environment around the equipment to prevent debris from affecting the normal operation of the equipment.

By understanding the key points of High-torque 2-shaft shredder operation and maintenance, you can improve equipment reliability and work efficiency and reduce operating costs.

What Else Might You Learn?

SIDSA focuses on technological research and innovation in the field of waste pretreatment

Product

SIDSA focuses on technological research and innovation in the field of waste pretreatment