Lithium batteries

Release Time:

Nov 11,2024

Process introduction:

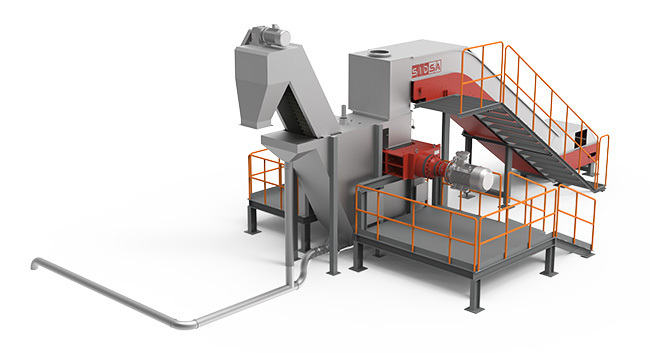

This process is primarily designed for the shredding and recycling of lithium batteries, suitable for shredding waste lithium batteries while they are still charged. The system adopts a two-stage shredding process and features a sealed chamber, scraper conveyor, oxygen analysis system, fire extinguishing device, and safety explosion relief device. The waste power lithium batteries are fed into the sealed chamber by a high-angle conveyor. At this point, both the sealed chamber and the crushing chamber are pre-charged with nitrogen. During the nitrogen charging process, the exhaust gas is discharged through a one-way valvet. Once the oxygen content in the shredding chamber reaches the set value, the materials fall into the shredding chamber and undergo two-stage shredding under nitrogen blanketing. The materials are shredded to a final size of 30-50mm and then conveyed to the next process by a scraper conveyor.

Advantages of the solution:

- Widely applicable and suitable for various types of batteries

- Hydraulic frame opening for easy maintenance, saving time

- Wear-resistant lining in the shredding chamber for durability, reducing repair costs

- Automatic feed adjustment for efficient shredding and increased output

- Automatic discharge of unshreddable materials, protecting the equipment without downtime

- Simple process, automated control, saving labor costs.

Intelligent detection for coordinated production, ensuring safe operation

What Else Might You Learn?

SIDSA focuses on technological research and innovation in the field of waste pretreatment

Product

SIDSA focuses on technological research and innovation in the field of waste pretreatment