Exploring the Benefits and Features of RHS Industrial Shredders in Manufacturing

Release Time:

May 01,2025

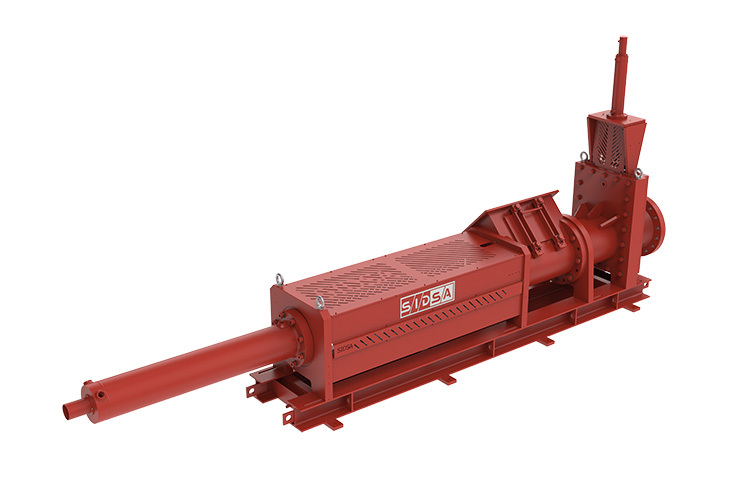

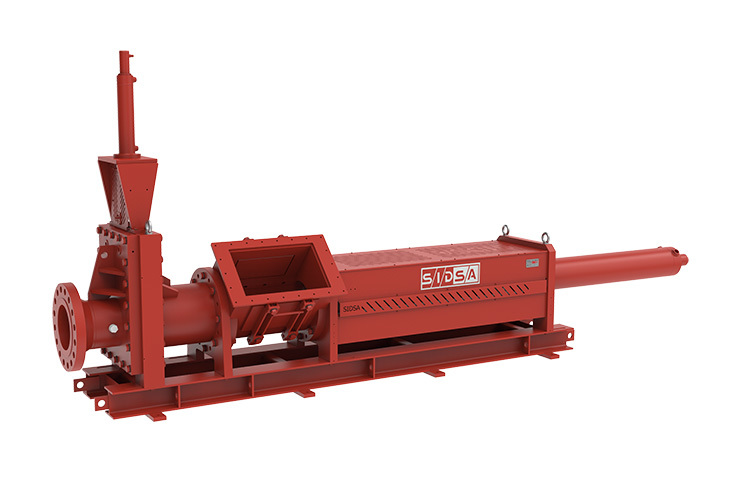

In the realm of manufacturing and processing machinery, RHS industrial shredders stand out for their versatility and efficiency in handling various materials. These robust machines are integral to the operations of companies looking to streamline their production processes and enhance waste management strategies. By breaking down large quantities of materials into smaller, more manageable pieces, RHS industrial shredders offer a range of benefits that support both operational efficiency and environmental sustainability.

One of the primary advantages of using RHS industrial shredders is their ability to handle diverse materials, including plastics, metals, paper, and electronic waste. This flexibility allows manufacturers to process a wide array of inputs without the need for specialized equipment for each material type. As a result, companies can save on costs associated with purchasing and maintaining multiple machines, while also simplifying their workflow.

Moreover, the shredding process plays a critical role in waste reduction. By minimizing the size of waste materials, RHS industrial shredders facilitate more efficient recycling and disposal. This not only helps companies comply with environmental regulations but also promotes sustainability by transforming waste into raw materials that can be reused in various applications. In an era where corporate responsibility and eco-friendliness are increasingly important, investing in industrial shredders aligns with modern manufacturing practices focused on reducing the ecological footprint.

Another key aspect of RHS industrial shredders is their advanced technology and design features. Many of these machines incorporate enhanced safety measures, energy-efficient motors, and customizable settings that allow operators to adjust shredding speeds and sizes according to their specific needs. This level of customization ensures that manufacturers can optimize their shredding processes for maximum productivity and minimal downtime.

Furthermore, the durability and reliability of RHS industrial shredders mean that companies can rely on these machines for continuous operation, even in high-demand environments. The robust construction and high-quality materials used in their manufacture contribute to their longevity, reducing the frequency of repairs and maintenance. This reliability is essential in maintaining production schedules and meeting customer demands without interruptions.

In conclusion, RHS industrial shredders are a vital component in the manufacturing sector, providing numerous benefits that enhance operational efficiency, support waste management efforts, and promote sustainability. Their versatility in handling various materials, combined with advanced technological features and reliable performance, makes them an invaluable investment for companies aiming to optimize their processes and contribute positively to the environment. As industries continue to evolve, embracing machinery like RHS industrial shredders will undoubtedly play a pivotal role in shaping a more efficient and sustainable future.

One of the primary advantages of using RHS industrial shredders is their ability to handle diverse materials, including plastics, metals, paper, and electronic waste. This flexibility allows manufacturers to process a wide array of inputs without the need for specialized equipment for each material type. As a result, companies can save on costs associated with purchasing and maintaining multiple machines, while also simplifying their workflow.

Moreover, the shredding process plays a critical role in waste reduction. By minimizing the size of waste materials, RHS industrial shredders facilitate more efficient recycling and disposal. This not only helps companies comply with environmental regulations but also promotes sustainability by transforming waste into raw materials that can be reused in various applications. In an era where corporate responsibility and eco-friendliness are increasingly important, investing in industrial shredders aligns with modern manufacturing practices focused on reducing the ecological footprint.

Another key aspect of RHS industrial shredders is their advanced technology and design features. Many of these machines incorporate enhanced safety measures, energy-efficient motors, and customizable settings that allow operators to adjust shredding speeds and sizes according to their specific needs. This level of customization ensures that manufacturers can optimize their shredding processes for maximum productivity and minimal downtime.

Furthermore, the durability and reliability of RHS industrial shredders mean that companies can rely on these machines for continuous operation, even in high-demand environments. The robust construction and high-quality materials used in their manufacture contribute to their longevity, reducing the frequency of repairs and maintenance. This reliability is essential in maintaining production schedules and meeting customer demands without interruptions.

In conclusion, RHS industrial shredders are a vital component in the manufacturing sector, providing numerous benefits that enhance operational efficiency, support waste management efforts, and promote sustainability. Their versatility in handling various materials, combined with advanced technological features and reliable performance, makes them an invaluable investment for companies aiming to optimize their processes and contribute positively to the environment. As industries continue to evolve, embracing machinery like RHS industrial shredders will undoubtedly play a pivotal role in shaping a more efficient and sustainable future.

What Else Might You Learn?

SIDSA focuses on technological research and innovation in the field of waste pretreatment

Product

SIDSA focuses on technological research and innovation in the field of waste pretreatment