Innovative Waste Management: Leveraging 2-Shaft Shredders for Sustainable Alternative Fuel Generation

Release Time:

May 12,2025

Innovative Waste Management: Leveraging 2-Shaft Shredders for Sustainable Alternative Fuel Generation

Table of Contents

- 1. Introduction to Waste Management and Alternative Fuels

- 2. The Role of 2-Shaft Shredders in Waste Processing

- 3. Understanding How 2-Shaft Shredders Operate

- 4. Key Benefits of Utilizing 2-Shaft Shredders

- 5. Applications of 2-Shaft Shredders in Various Industries

- 6. Implementing 2-Shaft Shredders for Alternative Fuel Generation

- 7. The Environmental Impact of 2-Shaft Shredders

- 8. The Future of Alternative Fuels and Waste Management

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Waste Management and Alternative Fuels

In the contemporary landscape of waste management, the emphasis on sustainability and renewable energy sources has never been more vital. As global populations grow and consumption increases, the challenge of managing waste efficiently while minimizing environmental impact is paramount. One innovative solution that has gained traction is the use of **2-shaft shredders** in the conversion of waste into alternative fuels. These machines are designed to process various waste materials, enabling their transformation into energy sources that can power industries, reduce landfill usage, and contribute to a circular economy.

2. The Role of 2-Shaft Shredders in Waste Processing

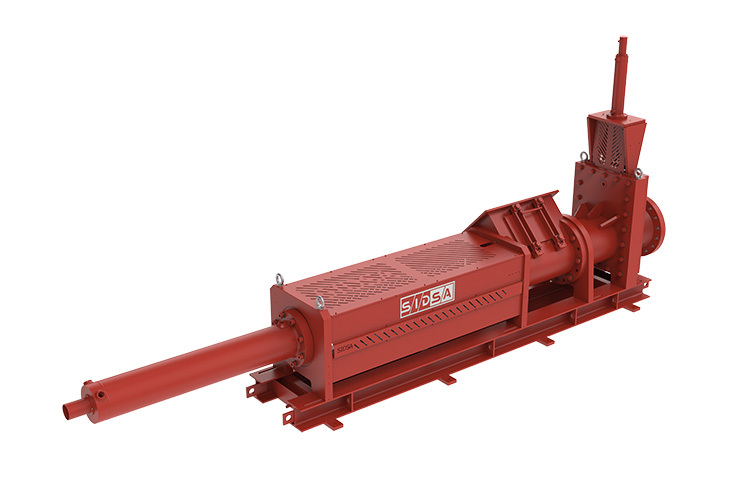

2-shaft shredders play a crucial role in waste processing systems by breaking down large and bulky materials into smaller, more manageable pieces. These shredders work by utilizing two rotating shafts equipped with sharp blades. As waste materials are fed into the shredder, they are pulled into the blades, which efficiently cut and crush them. This not only facilitates easier handling and transportation but also prepares the materials for subsequent processing steps.

The primary role of 2-shaft shredders in waste management includes:

- **Reducing Volume**: Shredding waste significantly reduces its physical volume, making storage and transportation more efficient.

- **Enhancing Material Recovery**: By breaking down materials, these shredders allow for better separation and recovery of recyclables and valuable materials.

- **Facilitating Alternative Fuel Production**: Shredded waste can be converted into alternative fuels, thus contributing to sustainable energy solutions.

3. Understanding How 2-Shaft Shredders Operate

The operational mechanics of 2-shaft shredders involve several critical components that work in harmony to achieve effective waste processing. The **shredding process** begins with the input of waste materials into the machine's feed hopper. Once the materials are loaded, the following steps occur:

1. **Feeding Mechanism**: The shredder's feeding system pulls waste materials into the cutting zone where the shredding action takes place.

2. **Shredding Action**: The two opposing shafts rotate in opposite directions, gripping the materials with sharp blades. This action effectively slices and shreds the waste into smaller fragments.

3. **Discharge**: The shredded materials are then discharged through a screen, which can be adjusted to control the size of the output particles. This ensures that the final product meets specific requirements for further processing, such as conversion into alternative fuels.

The versatility of 2-shaft shredders makes them suitable for various types of waste, including municipal solid waste, industrial waste, and construction debris.

4. Key Benefits of Utilizing 2-Shaft Shredders

The adoption of 2-shaft shredders in waste management systems presents numerous benefits that align with the goals of sustainability and efficiency. Key advantages include:

- **Cost-Effectiveness**: By reducing waste volume and improving material recovery, organizations can significantly lower disposal costs and enhance profitability.

- **Versatility**: 2-shaft shredders can handle a wide range of materials, including plastics, metals, wood, and organics, making them adaptable to different waste streams.

- **Improved Safety**: Shredding waste reduces the risk of hazardous materials and sharp objects causing injury during handling and transport.

- **Environmental Benefits**: By converting waste into alternative fuels, these shredders help reduce greenhouse gas emissions and reliance on fossil fuels, supporting environmental sustainability.

- **Enhanced Energy Recovery**: The shredded materials can be processed into various forms of alternative fuels, such as refuse-derived fuel (RDF) or biomass, contributing to renewable energy initiatives.

5. Applications of 2-Shaft Shredders in Various Industries

The versatility of 2-shaft shredders allows for their application across multiple industries, enhancing waste management strategies and supporting alternative fuel generation. Key applications include:

- **Municipal Waste Management**: Local governments utilize 2-shaft shredders to process household waste, ensuring effective waste reduction and resource recovery.

- **Industrial Manufacturing**: Factories employ shredders to manage production scraps, reducing waste and enabling the recycling of valuable materials.

- **Construction and Demolition**: In the construction sector, 2-shaft shredders are used to process wood, concrete, and other debris, transforming waste into reusable materials or fuels.

- **Agriculture**: Agricultural waste, such as crop residues and plant materials, can be shredded to create biomass fuels or compost, promoting sustainable practices.

6. Implementing 2-Shaft Shredders for Alternative Fuel Generation

The implementation of 2-shaft shredders in waste management systems requires careful planning and consideration. To effectively integrate these machines for alternative fuel generation, organizations must follow several key steps:

1. **Assess Waste Streams**: Identify the types and volumes of waste materials generated to determine the appropriate shredding technology and capacity.

2. **Select the Right Shredder**: Choose a 2-shaft shredder that meets the specific requirements of the waste materials, including size, type, and desired output quality.

3. **Design the Processing System**: Create a comprehensive waste processing system that incorporates shredders, screening, and other necessary equipment for efficient material recovery and fuel generation.

4. **Train Personnel**: Ensure that staff members are adequately trained in operating and maintaining the shredders, as well as managing the overall waste processing system.

5. **Monitor and Optimize Performance**: Regularly evaluate the performance of the shredders and the waste management system to identify areas for improvement and optimization.

By following these steps and investing in the right technology, organizations can successfully implement 2-shaft shredders to enhance waste management practices and contribute to alternative fuel generation.

7. The Environmental Impact of 2-Shaft Shredders

The environmental implications of using 2-shaft shredders extend beyond waste reduction. By facilitating the transformation of waste into alternative fuels, these machines play a vital role in fostering a more sustainable future. Key environmental impacts include:

- **Waste Diversion**: Shredders significantly reduce the amount of waste sent to landfills, thereby decreasing landfill-related environmental concerns.

- **Energy Recovery**: By converting waste into usable fuels, 2-shaft shredders contribute to renewable energy production and reduce the reliance on traditional fossil fuels.

- **Reduction of Greenhouse Gas Emissions**: The use of alternative fuels derived from waste leads to lower greenhouse gas emissions compared to conventional fossil fuels, mitigating climate change and its associated impacts.

8. The Future of Alternative Fuels and Waste Management

The future of alternative fuels and waste management is poised for growth and innovation, primarily driven by advancements in technology and increased awareness of environmental sustainability. As we look ahead, several trends are expected to shape this landscape:

- **Increased Investment in Technology**: The demand for efficient waste processing solutions will drive investments in advanced shredding technologies, including automation and smart systems.

- **Growing Adoption of Circular Economy Principles**: Organizations will increasingly adopt circular economy practices, focusing on waste reduction, reuse, and recycling, with 2-shaft shredders playing a pivotal role in this transition.

- **Enhanced Policy Support**: Governments and regulatory bodies are likely to implement policies that promote alternative fuel generation and penalize excessive waste, encouraging industries to adopt shredding technologies.

As these trends continue to evolve, 2-shaft shredders will remain integral to innovative waste management solutions, supporting sustainable alternative fuel generation and environmental stewardship.

9. Frequently Asked Questions

What types of materials can be processed with a 2-shaft shredder?

2-shaft shredders are versatile and can handle a wide variety of materials, including plastics, metals, wood, paper, and organic waste.

How does shredding improve waste management efficiency?

Shredding reduces the volume of waste, makes it easier to transport and process, and enhances the recovery of recyclable materials, contributing to a more efficient waste management system.

Can 2-shaft shredders be customized for specific applications?

Yes, many manufacturers offer customizable options for 2-shaft shredders, allowing organizations to tailor the machines to their specific waste processing needs.

What are the environmental benefits of using 2-shaft shredders?

2-shaft shredders help reduce landfill waste, lower greenhouse gas emissions, and facilitate the generation of renewable alternative fuels, contributing to a more sustainable environment.

How can organizations implement 2-shaft shredders in their waste management systems?

Organizations can implement 2-shaft shredders by assessing their waste streams, selecting the right shredder, designing an efficient processing system, training personnel, and continuously monitoring performance.

10. Conclusion

The innovative use of **2-shaft shredders** in waste management represents a significant advancement in the quest for sustainable alternative fuel generation. These machines not only enhance efficiency and reduce waste volume but also play a critical role in transforming waste into valuable energy resources. As industries continue to embrace environmentally responsible practices, the importance of 2-shaft shredders will only grow. By investing in these technologies, organizations can contribute to a greener future while ensuring effective waste management and resource recovery. The journey toward sustainability necessitates collaboration and innovation, and 2-shaft shredders are at the forefront of this essential movement.

What Else Might You Learn?

SIDSA focuses on technological research and innovation in the field of waste pretreatment

Product

SIDSA focuses on technological research and innovation in the field of waste pretreatment