Maximizing Efficiency: The Role of Primary Shredders in RDF Plant Operations

Release Time:

May 09,2025

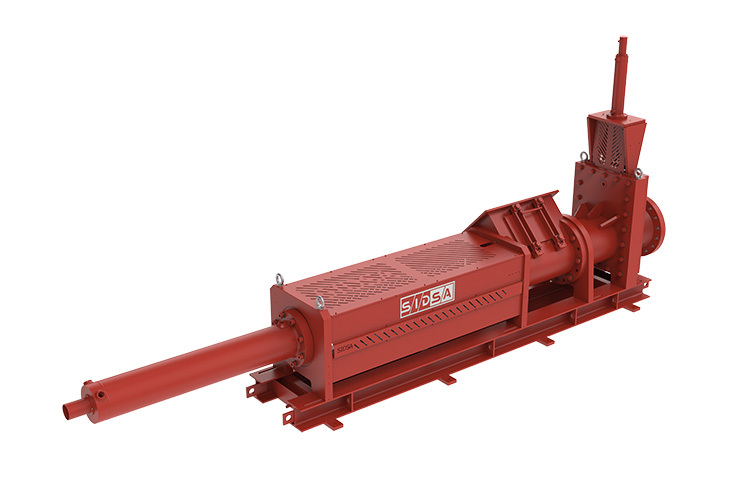

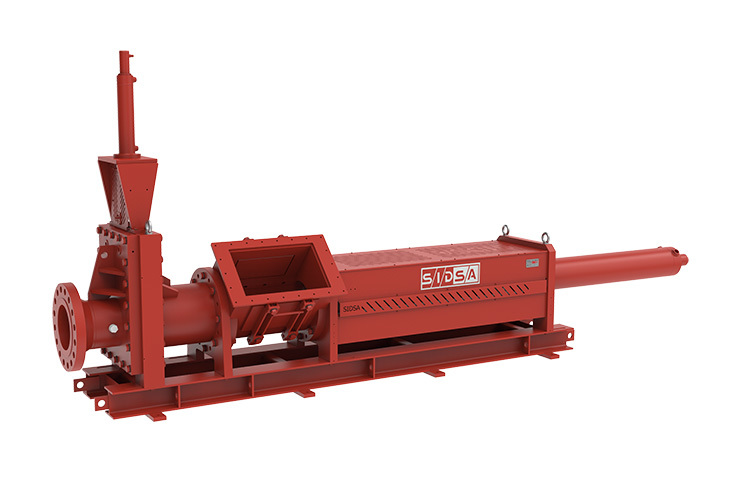

In Refuse-Derived Fuel (RDF) plants, the primary shredder plays a crucial role in the initial size reduction of various waste materials. These machines are designed to handle a diverse range of feedstock, including municipal solid waste, industrial waste, and biomass. The shredding process not only prepares the material for subsequent processing stages but also significantly influences the quality and consistency of the RDF produced.

One of the key functions of a primary shredder is to reduce the size of the feed material to a manageable level. Typically, this involves breaking down larger items into smaller pieces, allowing for easier handling and improved separation during the sorting and processing stages. The efficiency of this size reduction process is vital, as it directly impacts the throughput of the RDF plant.

Primary shredders are equipped with various features and technologies that enhance their performance. For instance, advanced cutting systems and blade configurations allow for optimized shredding, resulting in uniform particle sizes. This uniformity is critical, as it aids in achieving better combustion characteristics when the RDF is later used as an alternative fuel source. Furthermore, adjustable settings enable operators to tailor the shredding process based on the specific characteristics of the incoming waste, thereby maximizing efficiency.

Another significant aspect of primary shredders is their ability to reduce contaminants within the feed material. By effectively shredding and homogenizing the waste, these machines can help in the removal of non-combustible materials and impurities that may hinder the quality of RDF. Consequently, this not only ensures compliance with regulatory standards but also enhances the overall performance of the energy recovery system.

Moreover, the selection of a primary shredder should consider factors such as energy efficiency, maintenance requirements, and adaptability to varying waste compositions. Investing in a high-quality primary shredder can lead to substantial long-term savings by minimizing operational downtime and maintenance costs, while also optimizing energy consumption.

In conclusion, primary shredders are an integral component of RDF plants, playing a pivotal role in enhancing processing efficiency and the quality of the final product. By understanding the technical nuances and operational benefits of these machines, operators can make informed decisions that will contribute to the overall success of their waste management and energy recovery initiatives.

One of the key functions of a primary shredder is to reduce the size of the feed material to a manageable level. Typically, this involves breaking down larger items into smaller pieces, allowing for easier handling and improved separation during the sorting and processing stages. The efficiency of this size reduction process is vital, as it directly impacts the throughput of the RDF plant.

Primary shredders are equipped with various features and technologies that enhance their performance. For instance, advanced cutting systems and blade configurations allow for optimized shredding, resulting in uniform particle sizes. This uniformity is critical, as it aids in achieving better combustion characteristics when the RDF is later used as an alternative fuel source. Furthermore, adjustable settings enable operators to tailor the shredding process based on the specific characteristics of the incoming waste, thereby maximizing efficiency.

Another significant aspect of primary shredders is their ability to reduce contaminants within the feed material. By effectively shredding and homogenizing the waste, these machines can help in the removal of non-combustible materials and impurities that may hinder the quality of RDF. Consequently, this not only ensures compliance with regulatory standards but also enhances the overall performance of the energy recovery system.

Moreover, the selection of a primary shredder should consider factors such as energy efficiency, maintenance requirements, and adaptability to varying waste compositions. Investing in a high-quality primary shredder can lead to substantial long-term savings by minimizing operational downtime and maintenance costs, while also optimizing energy consumption.

In conclusion, primary shredders are an integral component of RDF plants, playing a pivotal role in enhancing processing efficiency and the quality of the final product. By understanding the technical nuances and operational benefits of these machines, operators can make informed decisions that will contribute to the overall success of their waste management and energy recovery initiatives.

What Else Might You Learn?

SIDSA focuses on technological research and innovation in the field of waste pretreatment

Product

SIDSA focuses on technological research and innovation in the field of waste pretreatment