Alternative fuel-example 2

Release Time:

Nov 11,2024

Process introduction:

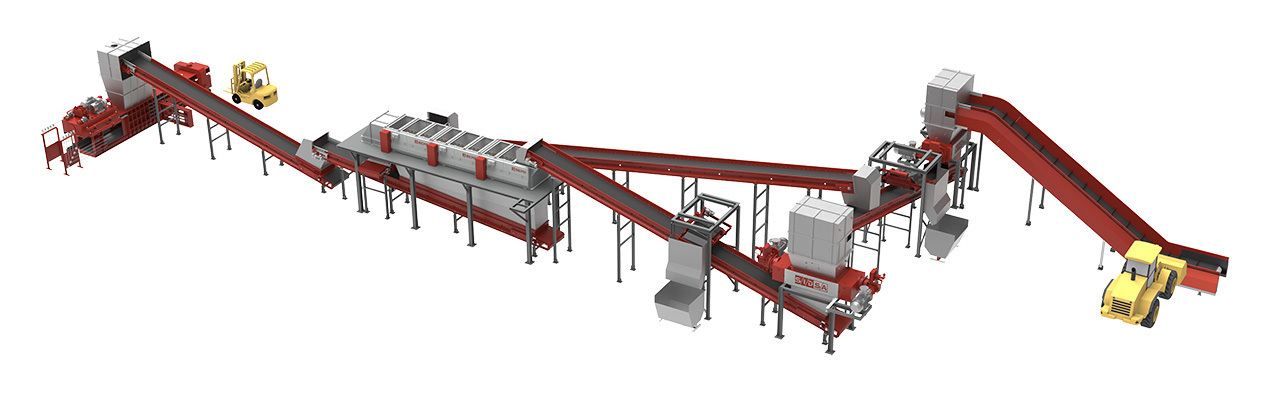

The SIDSA alternative fuel process is primarily designed for resource recovery of high-calorific industrial waste such as waste textiles, waste leather, waste wood products, waste paper, waste rubber, waste plastics, and waste composite packaging materials. This system utilizes a closed-loop process with dual-stage shredding and screening. It efficiently shreds various complex materials while ensuring a high throughput, safely producing high-quality alternative fuel to meet different customer needs.

Advantages of the solution:

- The process is simple, with a compact layout, saving investment costs

- Modular design concept for easy maintenance

- Blades are wear-resistant and durable, with low operating and maintenance costs

- Low-speed, high-torque design for high shredding efficiency

- Closed-loop process, with an granulometry qualification rate of up to 95%

- Automated operation effectively reduces labor costs

- Intelligent monitoring and protection ensure safe and reliable operation.

- Capable of handling complex materials, with a wide range of applications

What Else Might You Learn?

SIDSA focuses on technological research and innovation in the field of waste pretreatment

Product

SIDSA focuses on technological research and innovation in the field of waste pretreatment