General Industrial Solid Waste

Release Time:

Dec 18,2024

Process Introduction:

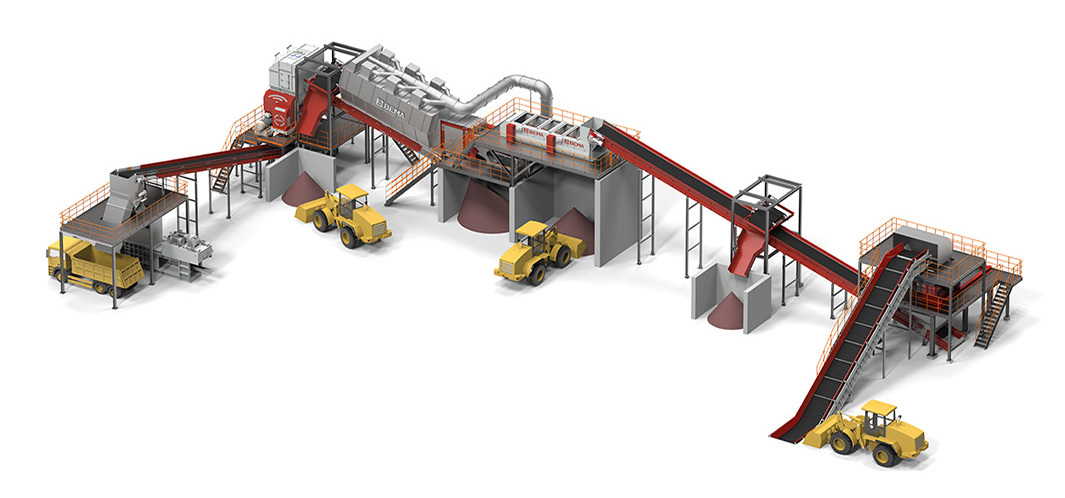

This process is designed for resource recovery of general industrial solid waste and other mixed waste. It mainly consists of a pre-shredder and fine shredder, magnetic separator(s), disc screen(s), wind shifter(s), fire protection systems, dust removal systems, and a centralized control system.

By combining different functional equipment, the system can sort waste into four components: soil and debris, inert non-combustibles, recyclable metals, and lightweight combustibles.

Finally, a single-shaft fine shredder processes the lightweight combustible materials into high-quality alternative fuel of the particle size required by the customer, achieving the resource utilization of mixed waste.

Advantages of the solution:

- Simple process and compact layout, reducing CAPEX.

- Able to pre-screen soil and debris, improving the operating environment and reducing equipment wear.

- Modular design concept ensures easy maintenance and low operational costs.

- Adjustable discharge screen apertures ensure a high product qualification rate (up to 95%).

- High degree of automation reducing labor costs.

- Intelligent monitoring and protection system ensures safe and reliable operation.

- High adaptability, capable of handling various waste types with a wide range of applications.

What Else Might You Learn?

SIDSA focuses on technological research and innovation in the field of waste pretreatment

Product

SIDSA focuses on technological research and innovation in the field of waste pretreatment