Unlocking Sustainability: The Role of Textile Recycling Shredders in Eco-Friendly Manufacturing

Release Time:

May 16,2025

Unlocking Sustainability: The Role of Textile Recycling Shredders in Eco-Friendly Manufacturing

Table of Contents

1. Introduction to Textile Recycling Shredders and Sustainability

2. Understanding Textile Waste in the Manufacturing Industry

2.1 The Impact of Textile Waste on the Environment

2.2 Statistics on Textile Waste Generation

3. How Textile Recycling Shredders Work

3.1 Mechanisms of Shredding Technology

3.2 Types of Textile Recycling Shredders

4. Benefits of Using Textile Recycling Shredders

4.1 Environmental Benefits

4.2 Economic Benefits

4.3 Social Benefits

5. Challenges in Textile Recycling and Shredding

5.1 Quality of Recycled Materials

5.2 Technological Limitations

6. Future Trends in Textile Recycling Shredding Technology

6.1 Innovations in Recycling Processes

6.2 The Role of Automation in Shredding

7. Case Studies: Successful Implementation of Textile Recycling Shredders

8. Conclusion: The Path Forward for Eco-Friendly Manufacturing

9. FAQs about Textile Recycling Shredders

1. Introduction to Textile Recycling Shredders and Sustainability

In today's rapidly changing world, sustainability has become a paramount concern for industries globally. The textile industry, notorious for its substantial environmental footprint, is now focusing on eco-friendly practices. One of the pivotal technologies driving this change is **textile recycling shredders**. These machines are crucial in reducing textile waste and promoting a circular economy by transforming discarded fabrics into reusable materials. This article explores the vital role of textile recycling shredders in fostering sustainability within manufacturing processes.

2. Understanding Textile Waste in the Manufacturing Industry

The textile industry is among the largest contributors to global waste. Every year, millions of tons of textiles are discarded, leading to environmental degradation and significant economic losses.

2.1 The Impact of Textile Waste on the Environment

Textile waste poses severe environmental threats. When textiles are thrown away, they often end up in landfills, where they take decades to decompose. During this process, they release harmful greenhouse gases and toxins into the soil and water. Moreover, the production of new textiles consumes vast resources, including water, energy, and chemicals, exacerbating environmental issues.

2.2 Statistics on Textile Waste Generation

Statistics indicate that the average person generates approximately 70 pounds of textile waste annually, leading to around 11 million tons in the United States alone. This staggering figure underscores the urgency for effective recycling solutions, such as shredding technology, to mitigate waste and promote sustainability.

3. How Textile Recycling Shredders Work

Textile recycling shredders are engineered to process various textile materials, including cotton, polyester, and blends, transforming them into smaller pieces suitable for reuse or recycling.

3.1 Mechanisms of Shredding Technology

Shredding technology employs an array of mechanical processes, including cutting, tearing, and grinding, to disintegrate textile waste. Modern shredders utilize **high-speed rotors** and durable blades to efficiently handle diverse fabric types, ensuring a thorough breakdown of materials.

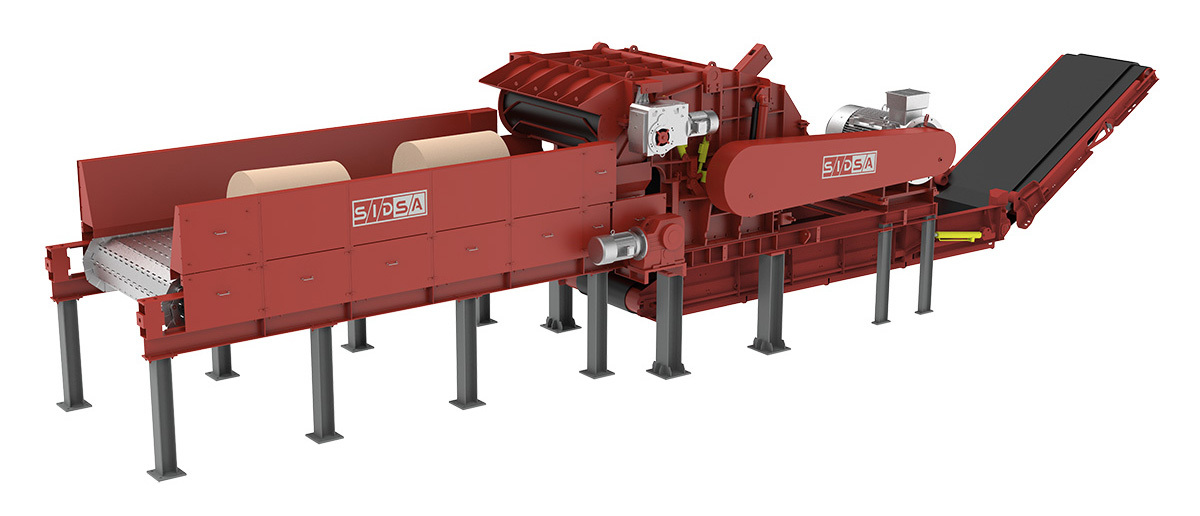

3.2 Types of Textile Recycling Shredders

Various types of shredders are available, each designed for specific applications:

- **Single-Shaft Shredders**: Ideal for general textile waste, these shredders operate with a single rotor, providing robust performance for a wide range of materials.

- **Two-Shaft Shredders**: These machines employ two rotating shafts, allowing for more controlled shredding and suitable for larger items like clothing and upholstery.

- **Granulators**: Designed for producing fine particles, granulators are effective for recycling blended textiles, ensuring compatibility with various recycling processes.

4. Benefits of Using Textile Recycling Shredders

The integration of textile recycling shredders into manufacturing processes offers numerous advantages that contribute to sustainability.

4.1 Environmental Benefits

By reducing textile waste and promoting recycling, shredders significantly decrease landfill usage and lower greenhouse gas emissions. They enable the recovery of valuable resources, minimizing the need for virgin materials and promoting a more sustainable manufacturing cycle.

4.2 Economic Benefits

Investing in textile recycling shredders can lead to substantial economic gains. Companies can reduce disposal costs and transform waste into revenue by selling shredded materials to manufacturers for reuse. Additionally, operational efficiencies can be achieved through streamlined recycling processes.

4.3 Social Benefits

The adoption of textile recycling technology fosters social responsibility within the industry. By promoting sustainable practices, companies can enhance their brand reputation and appeal to environmentally conscious consumers, ultimately driving sales and customer loyalty.

5. Challenges in Textile Recycling and Shredding

Despite the advantages of textile recycling shredders, several challenges must be addressed to maximize their effectiveness.

5.1 Quality of Recycled Materials

One of the primary challenges is ensuring the quality of recycled materials. Contamination from non-textile components can compromise the integrity of shredded materials, affecting their usability in new production processes. It is vital to implement rigorous sorting and cleaning protocols to enhance material quality.

5.2 Technological Limitations

While shredding technology has advanced significantly, certain limitations still exist. For example, some fibers may require specialized shredding processes to achieve the desired particle size, which can be costly and resource-intensive.

6. Future Trends in Textile Recycling Shredding Technology

As the demand for sustainable practices grows, so too does the innovation in textile recycling shredding technology.

6.1 Innovations in Recycling Processes

Emerging technologies, such as **chemical recycling**, are gaining traction alongside traditional shredding methods. These processes break down textiles at a molecular level, allowing for the recovery of raw materials that can be repurposed into new fabrics.

6.2 The Role of Automation in Shredding

Automation is poised to revolutionize the textile recycling industry. Automated sorting and shredding systems can enhance efficiency, reduce labor costs, and improve the overall quality of recycled materials. As technology advances, we expect to see more intelligent shredders that can adapt to various textile types and conditions seamlessly.

7. Case Studies: Successful Implementation of Textile Recycling Shredders

Various companies worldwide have successfully integrated textile recycling shredders into their operations, showcasing the viability of this technology in promoting sustainability.

For instance, a leading European textile manufacturer adopted shredding technology to process post-consumer textiles. By implementing a closed-loop system, they transformed waste into new fabric, reducing their reliance on virgin materials by over 40%. This initiative not only improved their sustainability credentials but also resulted in significant cost savings.

8. Conclusion: The Path Forward for Eco-Friendly Manufacturing

The role of textile recycling shredders in eco-friendly manufacturing is pivotal. By facilitating the recycling of textile waste, these machines contribute significantly to environmental protection, economic efficiency, and social responsibility. As technology continues to evolve, the industry can look forward to a future where textile waste is minimized, resources are conserved, and sustainability is ingrained in manufacturing practices.

9. FAQs about Textile Recycling Shredders

1. What are textile recycling shredders used for?

Textile recycling shredders are designed to break down discarded fabrics into smaller pieces, making them suitable for reuse or recycling in various manufacturing processes.

2. How do textile shredders contribute to sustainability?

By reducing textile waste entering landfills and enabling the recovery of valuable materials, shredders play a critical role in promoting sustainable practices within the textile industry.

3. What types of fabrics can be processed by shredders?

Shredders can process a wide range of fabrics, including cotton, polyester, and blends, although specific shredders may be designed for certain materials.

4. Can shredded textiles be reused?

Yes, shredded textiles can be repurposed into new fabrics, insulation material, and other products, significantly reducing the need for virgin materials.

5. What challenges do companies face when implementing shredding technology?

Companies may face challenges such as ensuring the quality of recycled materials and technological limitations that require specialized processes for certain textile types.

By understanding the essential role of textile recycling shredders in sustainable manufacturing, companies can make informed decisions that contribute to a greener future.

What Else Might You Learn?

SIDSA focuses on technological research and innovation in the field of waste pretreatment

Product

SIDSA focuses on technological research and innovation in the field of waste pretreatment