Maximizing Efficiency in Textile Recycling with Advanced Shredders

Release Time:

May 19,2025

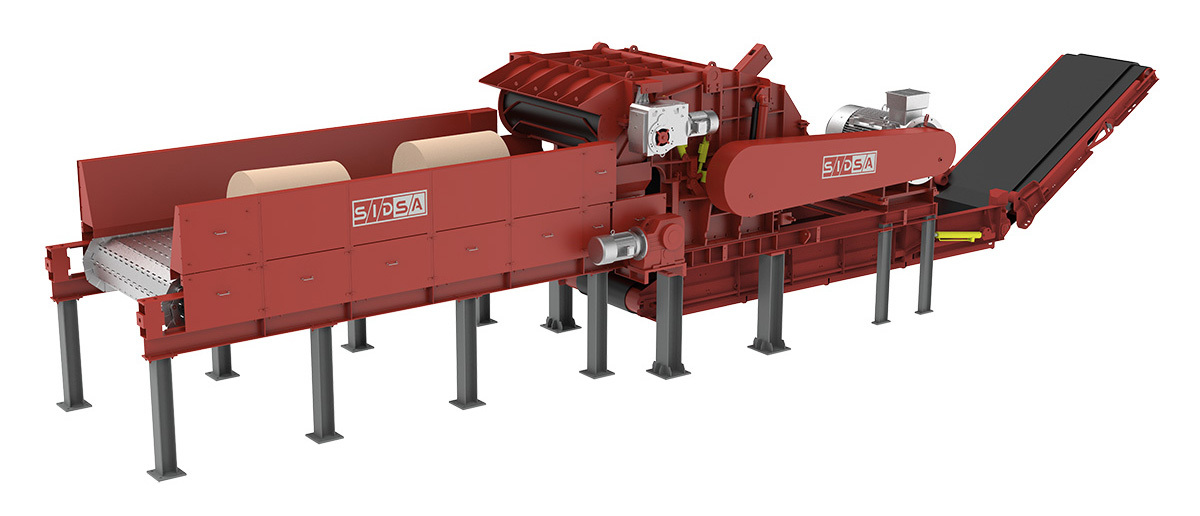

Textile recycling is becoming increasingly important as the world grapples with the environmental impacts of fast fashion and textile waste. One of the critical components in this recycling process is the textile recycling shredder, a machine specifically designed to break down various types of fabrics into manageable sizes for further processing. Understanding the mechanics and benefits of these shredders can greatly enhance the efficiency of textile recycling operations.

Textile recycling shredders utilize sharp blades and a robust design to shred materials like cotton, polyester, and blended fabrics. By processing these textiles, manufacturers can convert waste into valuable raw materials, thereby reducing landfill contributions and promoting a circular economy. One of the primary advantages of using a textile recycling shredder is the ability to increase the volume of material that can be processed. A well-designed shredder can handle large batches of textiles, significantly speeding up the recycling process.

Moreover, the technology behind these shredders has evolved, incorporating features that enhance operational efficiency. For instance, some models are equipped with multiple cutting systems that allow for adjustable particle sizes. This flexibility is crucial as it accommodates various recycling requirements, enabling operators to produce consistent output tailored to the needs of downstream processes, such as further shredding or granulation.

Another pivotal aspect of textile recycling shredders is their role in reducing energy consumption. Modern machines are engineered to operate at optimal efficiency, which not only maximizes production rates but also minimizes operational costs. By investing in a high-performance shredder, manufacturers can lower their carbon footprint while improving their bottom line.

Additionally, the integration of smart technology into textile recycling shredders is transforming the industry. Features such as real-time monitoring and diagnostic capabilities help operators maintain their machines more effectively. These innovations allow for predictive maintenance, reducing downtime and ensuring that the shredding operations run smoothly.

In conclusion, textile recycling shredders are indispensable tools in the quest for sustainable textile management. By adopting advanced shredding technology, manufacturers can not only streamline their recycling processes but also contribute to a greener future. As the industry continues to evolve, staying informed about the latest advancements in shredding technology will be key to maintaining competitive advantages and sustainability goals.

Textile recycling shredders utilize sharp blades and a robust design to shred materials like cotton, polyester, and blended fabrics. By processing these textiles, manufacturers can convert waste into valuable raw materials, thereby reducing landfill contributions and promoting a circular economy. One of the primary advantages of using a textile recycling shredder is the ability to increase the volume of material that can be processed. A well-designed shredder can handle large batches of textiles, significantly speeding up the recycling process.

Moreover, the technology behind these shredders has evolved, incorporating features that enhance operational efficiency. For instance, some models are equipped with multiple cutting systems that allow for adjustable particle sizes. This flexibility is crucial as it accommodates various recycling requirements, enabling operators to produce consistent output tailored to the needs of downstream processes, such as further shredding or granulation.

Another pivotal aspect of textile recycling shredders is their role in reducing energy consumption. Modern machines are engineered to operate at optimal efficiency, which not only maximizes production rates but also minimizes operational costs. By investing in a high-performance shredder, manufacturers can lower their carbon footprint while improving their bottom line.

Additionally, the integration of smart technology into textile recycling shredders is transforming the industry. Features such as real-time monitoring and diagnostic capabilities help operators maintain their machines more effectively. These innovations allow for predictive maintenance, reducing downtime and ensuring that the shredding operations run smoothly.

In conclusion, textile recycling shredders are indispensable tools in the quest for sustainable textile management. By adopting advanced shredding technology, manufacturers can not only streamline their recycling processes but also contribute to a greener future. As the industry continues to evolve, staying informed about the latest advancements in shredding technology will be key to maintaining competitive advantages and sustainability goals.

What Else Might You Learn?

SIDSA focuses on technological research and innovation in the field of waste pretreatment

Product

SIDSA focuses on technological research and innovation in the field of waste pretreatment