Maximizing Efficiency in Textile Recycling: The Role of Shredders in Sustainable Manufacturing

Release Time:

May 17,2025

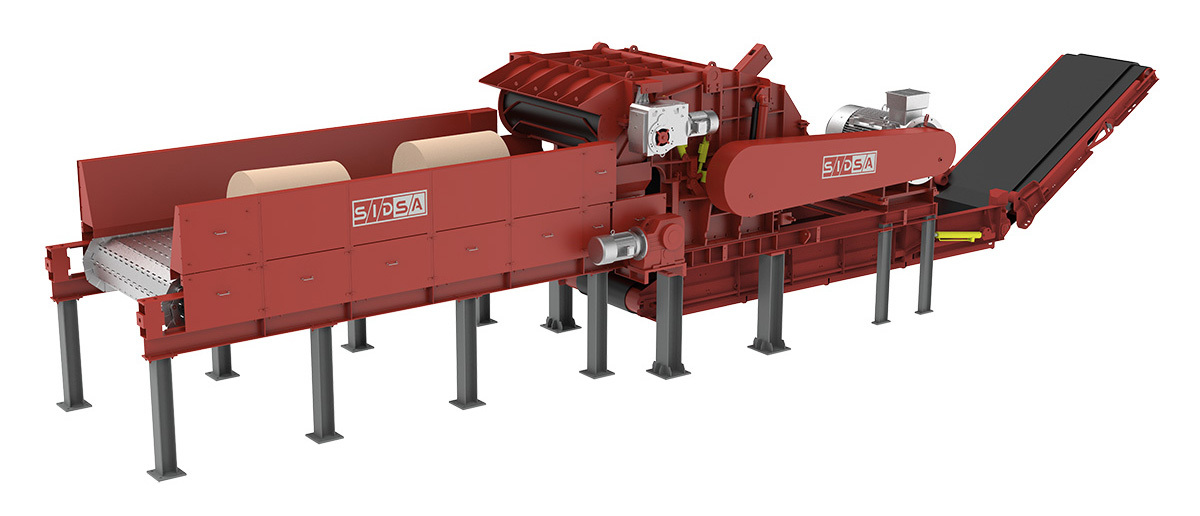

In today's environmentally conscious market, the textile recycling industry is gaining momentum as businesses seek sustainable practices. One critical component in this process is the textile recycling shredder, a machine designed to break down discarded fabrics into manageable sizes. Understanding the function and benefits of these shredders is vital for manufacturers looking to embrace more sustainable operations.

Textile recycling shredders serve multiple purposes. Primarily, they reduce the volume of waste, making it easier to transport and process. By shredding textiles, manufacturers can efficiently turn unwanted clothing and fabric scraps into raw materials for new products, such as insulation, carpet padding, or even new textiles. This not only minimizes landfill contributions but also supports the circular economy by keeping materials in use.

In addition to waste reduction, textile shredders improve resource recovery. Shredding textiles allows for the extraction of valuable fibers and materials, which can then be repurposed. This process is essential for companies aiming to lower their environmental footprint while also creating new revenue streams from recycled materials. Advanced shredding technologies can handle various textile types, including cotton, polyester, and blends, making them versatile tools in the recycling process.

When considering a textile recycling shredder, several factors come into play. Firstly, manufacturers should assess the shredder’s capacity and throughput capabilities. It’s crucial to select machinery that aligns with the volume of material your facility processes. Additionally, examining the shredder’s energy efficiency can lead to significant cost savings in the long run, as less energy consumption directly correlates with lower operational costs.

Another important consideration is the shredder's adaptability. As textile recycling demands evolve, having a flexible machine that can handle different materials and adjust to varying sizes is beneficial. This adaptability not only enhances operational efficiency but also future-proofs your investment against changing market needs.

Finally, maintenance and support are critical factors in the long-term performance of your shredder. Look for manufacturers that provide excellent service and readily available spare parts. Regular maintenance ensures that the machine operates at optimal efficiency and extends its lifespan, providing greater value for your investment.

In conclusion, textile recycling shredders play an indispensable role in modern manufacturing. They enhance sustainability, optimize resource recovery, and contribute to a more circular economy. By carefully considering capacity, energy efficiency, adaptability, and maintenance, manufacturers can select the right shredding solution to meet their operational needs while supporting environmental goals.

Textile recycling shredders serve multiple purposes. Primarily, they reduce the volume of waste, making it easier to transport and process. By shredding textiles, manufacturers can efficiently turn unwanted clothing and fabric scraps into raw materials for new products, such as insulation, carpet padding, or even new textiles. This not only minimizes landfill contributions but also supports the circular economy by keeping materials in use.

In addition to waste reduction, textile shredders improve resource recovery. Shredding textiles allows for the extraction of valuable fibers and materials, which can then be repurposed. This process is essential for companies aiming to lower their environmental footprint while also creating new revenue streams from recycled materials. Advanced shredding technologies can handle various textile types, including cotton, polyester, and blends, making them versatile tools in the recycling process.

When considering a textile recycling shredder, several factors come into play. Firstly, manufacturers should assess the shredder’s capacity and throughput capabilities. It’s crucial to select machinery that aligns with the volume of material your facility processes. Additionally, examining the shredder’s energy efficiency can lead to significant cost savings in the long run, as less energy consumption directly correlates with lower operational costs.

Another important consideration is the shredder's adaptability. As textile recycling demands evolve, having a flexible machine that can handle different materials and adjust to varying sizes is beneficial. This adaptability not only enhances operational efficiency but also future-proofs your investment against changing market needs.

Finally, maintenance and support are critical factors in the long-term performance of your shredder. Look for manufacturers that provide excellent service and readily available spare parts. Regular maintenance ensures that the machine operates at optimal efficiency and extends its lifespan, providing greater value for your investment.

In conclusion, textile recycling shredders play an indispensable role in modern manufacturing. They enhance sustainability, optimize resource recovery, and contribute to a more circular economy. By carefully considering capacity, energy efficiency, adaptability, and maintenance, manufacturers can select the right shredding solution to meet their operational needs while supporting environmental goals.

What Else Might You Learn?

SIDSA focuses on technological research and innovation in the field of waste pretreatment

Product

SIDSA focuses on technological research and innovation in the field of waste pretreatment