Transforming Waste into Resources: The Inner Workings of Textile Recycling Shredders

Release Time:

May 18,2025

Transforming Waste into Resources: The Inner Workings of Textile Recycling Shredders

Table of Contents

- Introduction to Textile Recycling

- The Importance of Textile Recycling

- What Are Textile Recycling Shredders?

- How Textile Recycling Shredders Work

- Types of Textile Recycling Shredders

- Benefits of Using Textile Recycling Shredders

- Choosing the Right Textile Recycling Shredder

- The Future of Textile Recycling

- Conclusion

- Frequently Asked Questions

Introduction to Textile Recycling

Textile recycling is an essential process in today's waste management and environmental conservation efforts. With millions of tons of textile waste generated annually, recycling these materials is crucial for reducing landfill contributions and conserving natural resources. By reprocessing used textiles into new products, we can significantly lower the environmental impact of the fashion industry and promote a circular economy.

The Importance of Textile Recycling

The importance of textile recycling cannot be overstated. With the global fashion industry rapidly evolving, the need for sustainable practices has become more urgent than ever. Here are some key reasons why textile recycling is vital:

Reducing Landfill Waste

Textiles contribute to a significant portion of landfill waste. By recycling fabrics, we can drastically reduce the volume of waste entering landfills, which not only conserves space but also minimizes harmful emissions and leachate from decomposing materials.

Conserving Resources

Recycling textiles helps conserve valuable resources such as water and energy. The production of new textiles requires vast amounts of both, and recycling reduces the demand for these resources.

Minimizing Environmental Pollution

The fashion industry is notorious for its environmental footprint. Textile recycling helps mitigate pollution by reducing the need for virgin materials and the chemical processes involved in their production.

Creating Employment Opportunities

The textile recycling sector creates jobs in collection, sorting, and processing operations, contributing to economic growth and providing employment in local communities.

What Are Textile Recycling Shredders?

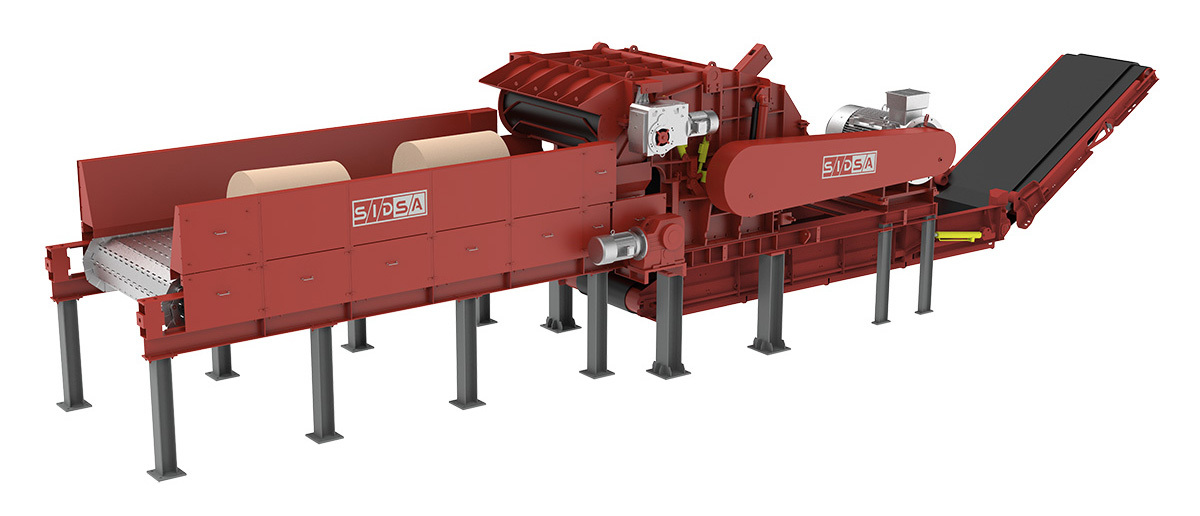

Textile recycling shredders are specialized machines designed to break down used fabrics into smaller, manageable pieces. These shredders play a crucial role in the recycling process by preparing textiles for further processing, such as baling or fiber extraction. They are engineered to handle various types of fabrics, including cotton, polyester, and blended materials.

How Textile Recycling Shredders Work

Understanding how textile recycling shredders work can illuminate their significance in the recycling process. Here’s a breakdown of the shredding process:

Feeding the Materials

Textile waste is first collected and sorted based on its type and condition. The sorted materials are then fed into the shredder through a conveyor belt or loading chute.

Cutting Mechanism

Once inside the shredder, the textiles encounter sharp blades that rotate at high speeds. These blades are designed to cut through different fabric types, ensuring a uniform cut size. The cutting mechanism can vary, with some shredders utilizing single-shaft, two-shaft, or four-shaft designs, depending on the intended application.

Size Reduction

As the textiles pass through the blades, they are reduced to smaller pieces, typically ranging from a few millimeters to several centimeters in size. This size reduction is crucial for efficient processing and subsequent recycling steps.

Discharge and Collection

After shredding, the processed textiles are discharged into a collection bin or conveyor belt, where they can be further sorted, baled, or transformed into new products.

Types of Textile Recycling Shredders

There are several types of textile recycling shredders, each designed for specific applications and fabric types. Here are the most common types:

Single-Shaft Shredders

Single-shaft shredders feature a single rotating shaft with fixed knives. They are ideal for shredding softer materials and provide a lower throughput compared to other types.

Two-Shaft Shredders

Two-shaft shredders consist of two parallel shafts, each equipped with sharp, intermeshing blades. This design allows for higher throughput and is well-suited for tougher fabrics.

Four-Shaft Shredders

Four-shaft shredders are designed for maximum versatility and efficiency. With two sets of blades rotating at different speeds, they can handle a wide variety of material types, making them ideal for mixed textile waste.

Granulators

Granulators are specialized shredders that produce very fine particles, often used for further processing into fibers or as raw materials for new products.

Benefits of Using Textile Recycling Shredders

Utilizing textile recycling shredders offers numerous advantages for businesses and the environment alike. Here are some key benefits:

Efficiency in Processing

Shredders streamline the recycling process by quickly and effectively breaking down textiles, reducing labor and time required for manual sorting and cutting.

Enhanced Material Recovery

By shredding textiles into smaller pieces, recyclers can recover more fibers and materials, leading to higher recycling rates and less waste.

Improved Quality of Recycled Materials

A consistent shred size enhances the quality of the recycled material, making it more suitable for reuse in new textile production.

Environmental Benefits

Using shredders contributes to a cleaner environment by reducing waste, conserving resources, and lowering carbon emissions associated with textile production.

Choosing the Right Textile Recycling Shredder

Selecting the appropriate textile recycling shredder is crucial for maximizing efficiency and effectiveness. Consider the following factors when making your choice:

Type of Material

Evaluate the types of textiles you will be processing. Different machines are suited for various materials, so choose a shredder that accommodates your specific needs.

Desired Output Size

Determine the required output size for your recycling process. Different shredders produce varying sizes, so align your choice with your operational requirements.

Throughput Capacity

Consider the volume of materials you need to process. Choose a machine with adequate throughput capacity to meet your production demands.

Budget

While investing in a quality shredder is essential, ensure that it fits within your budget. Compare features and specifications to find the best value for your investment.

The Future of Textile Recycling

As the world continues to grapple with environmental challenges, the future of textile recycling appears promising. Innovations in shredding technology are paving the way for more efficient processing methods and improved material recovery rates.

Technological Advancements

Emerging technologies, such as automation and artificial intelligence, are enhancing the performance of shredders, making them smarter and more efficient.

Increased Awareness and Regulations

With growing environmental awareness, consumers and governments alike are pushing for stricter regulations on textile waste management, driving the demand for effective recycling solutions.

Circular Economy Initiatives

The shift toward a circular economy is encouraging more businesses to adopt sustainable practices, including textile recycling, further solidifying the role of shredders in waste transformation.

Conclusion

Textile recycling shredders are indispensable tools in the quest to transform waste into valuable resources. By understanding the mechanics, benefits, and future potential of these machines, we can foster a more sustainable textile industry. Embracing textile recycling not only conserves resources and reduces waste but also contributes to a healthier planet for future generations.

Frequently Asked Questions

1. What types of textiles can be recycled using shredders?

Textile recycling shredders can process a wide variety of materials, including cotton, polyester, wool, and blended fabrics.

2. How can I determine the best shredder for my needs?

Consider the type of materials you will be processing, the desired output size, throughput capacity, and your budget when selecting a shredder.

3. What are the environmental benefits of textile recycling?

Textile recycling helps reduce landfill waste, conserve resources, minimize pollution, and support a circular economy.

4. How does shredding improve the recycling process?

Shredding textiles into smaller pieces enhances material recovery rates and improves the quality of the recycled output.

5. What advancements are being made in textile recycling technology?

Technological advancements, including automation and AI, are improving the efficiency and effectiveness of textile recycling shredders, paving the way for a more sustainable future.

What Else Might You Learn?

SIDSA focuses on technological research and innovation in the field of waste pretreatment

Product

SIDSA focuses on technological research and innovation in the field of waste pretreatment